A research was done by Hygiene Council in 2007, collected the top 31st area with most bacteria content.

| bacteria / inch2 | ||

| 1 | Toilet bowl | 3,200,000 |

| 2 | Kitchen drain | 567,845 |

| 3 | Sponge | 134,630 |

| 4 | Bathtub, near drain | 119,468 |

| 5 | Kitchen sink, near drain | 17,964 |

| 6 | Kitchen faucet handle | 13,227 |

| 7 | Bathroom faucet handle | 6,267 |

| 8 | Bathroom sink, near drain | 2,733 |

| 9 | Pet food dish, inside rim | 2,110 |

| 10 | Kitchen floor, in front of sink | 830 |

| 11 | Toilet floor, in front of toilet | 764 |

| 12 | Kitchen counter top | 488 |

| 13 | Bathroom counter top | 452 |

| 14 | Garbage bin | 411 |

| 15 | Dish towel | 408 |

| 16 | Toy | 345 |

| 17 | Kitchen tabletop | 344 |

| 18 | Refrigerator door | 319 |

| 19 | Home office phone | 319 |

| 20 | Toilet seat | 295 |

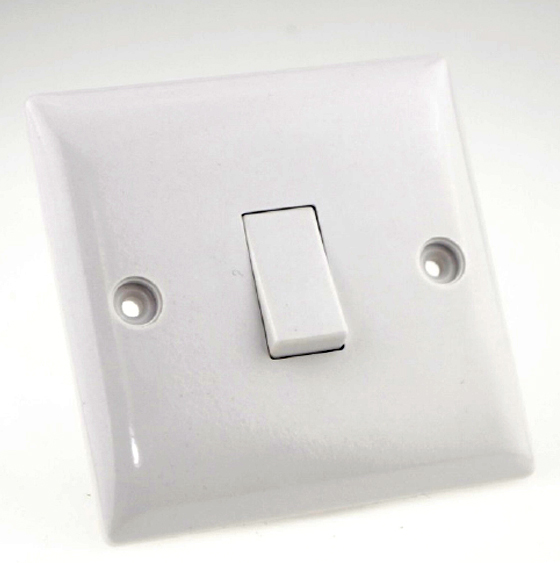

| 21 | Bathroom light switch | 217 |

| 22 | Microwave buttons | 214 |

| 23 | Kitchen chopping board | 194 |

| 24 | Child training potty | 191 |

| 25 | Infant changing mat | 190 |

| 26 | Kitchen phone | 133 |

| 27 | Bathroom door’s inside handle | 121 |

| 28 | Toilet’s flush handle | 83 |

| 29 | TV remote control | 70 |

| 30 | Home computer keyborad | 64 |

| 31 | Home computer mouse | 50 |

You may have no surprise to see the TOP rank is a toilet bowl, but you may surprise to see a light switch is in fact only slightly better than a toilet seat. Even worst, a toilet flush handle is way better than the light switch. Ask yourself, how often do you wash your hands after flashing the toilet, and how often do you wash your hands after switching off a light?

- WK AT-FIELD switches, provide a simple solution to this embarrassing situation.

- The surfaces of our AT-FIELD switches are ANTI-BACTERIAL.

- AT-FIELDed surfaces don’t kill the bacteria directly, but provide a very difficult environment where the bacteria cannot live for very long.

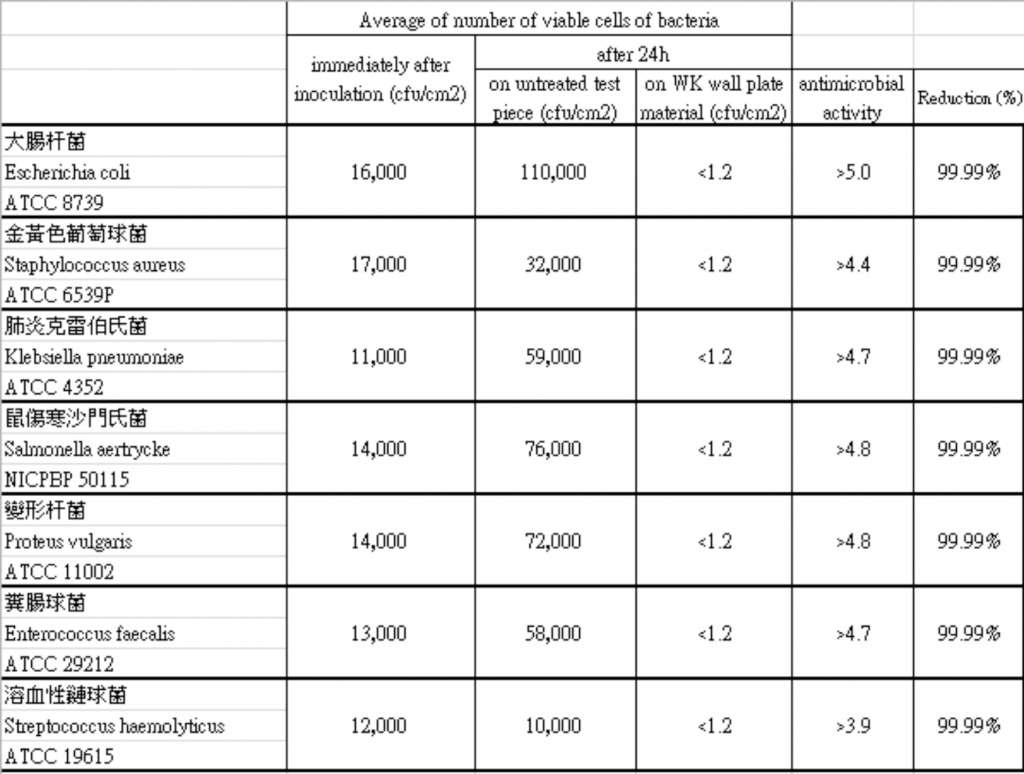

Below shown a material test report of WK AT-FIELD material. Bacteria usually grow on a normal surface, but on AT-FIELD surfaces, they are eliminated very effectively. AT-FIELD surfaces can achieve 99.99% reduction rate after 24hours.

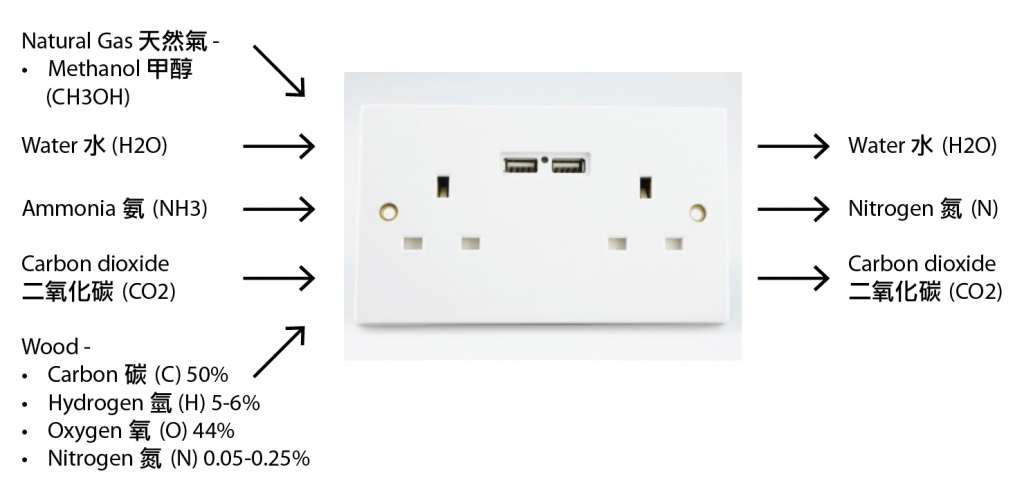

WK – AT-Field Series – CO2 Emission

| CO2 emission (kg/tonnes) | |

| AT-FIELD material | 1,000 |

| Polycarbonate (PC) | 1,600 |

| Polyethylene (PE) | 1,300 |

| Polypropylene (PP) | 1,400 |

| Polyvinyl chloride (PVC) | 1,700 |

WK – AT-Field Series – Energy saving in Production

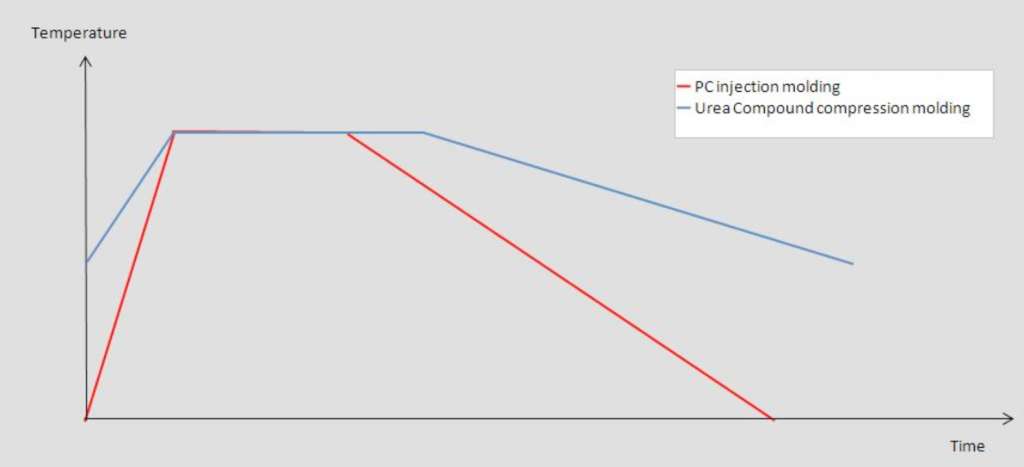

Common injection moulding requires extra energy to cool down the toolings and the components, so that the components is set and become solid.

However, AT-FIELD material can be manufactured by compression moulding, the material can be set at a much higher temperature. Hence the next cycle can start at a higher temperature, almost 50% energy is saved!!